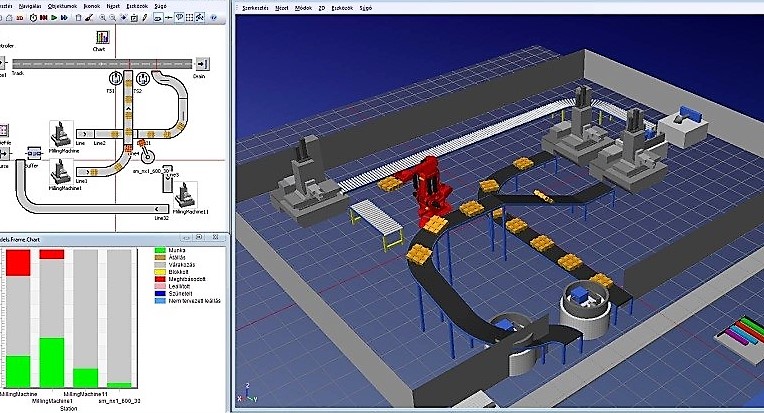

One of the main activities of the System Design Department is the solution and implementation of tasks aimed at increasing the efficiency of production and logistics systems. The objectives of the project work are very diverse, but most of the work is related to production-logistics systems, which are mainly the use of reserves, bottlenecks, production (production equipment) and logistics resources (warehouses, material handling equipment, workers). Due to the very high complexity of the systems, the tests are performed using efficient engineering design and modeling software, which makes it possible to model and simulate the processes in the system. We use Siemens Plant Simulation disk-event-driven simulation software, which specifically supports the modeling of production logistics processes. In addition to solving the logistics tasks of our project works at domestic multinational companies (Audi Hungaria Kft. Győr; Robert Bosch Energy and Body Systems Kft. And Robert Bosch Power Tool Kft. Miskolc; Magyar Suzuki Zrt. Esztergom) during the past more than ten years, the SME There are also needs in the sector for the rationalization of production and material supply processes, for the most efficient and economical production possible (D&D Drótáru Zrt.Miskolc; Akzo-Nobel Kft. Tiszaújváros; FlexiForce Kft. Debrecen; Platt 2003 Kft. Eger).

Contact

Dr. Richárd LADÁNYI, Head of Department, Department of System Design

E-mail: richard.ladanyi@bayzoltan.hu